Medication Shortages: How to Manage When Drugs Aren’t Available

Nov, 1 2025

Nov, 1 2025

When your hospital runs out of morphine, or the IV antibiotics your patient needs don’t arrive, it’s not just an inconvenience-it’s a crisis. Medication shortages aren’t rare glitches anymore. They’re a persistent, growing threat to patient care across the U.S., affecting everything from cancer treatments to emergency room protocols. As of 2023, nearly one in five essential hospital medications faced some level of shortage, and the average length of these shortages has stretched to nearly 10 months. This isn’t a problem you can wait out. You need a plan-and you need it now.

What’s Really Causing the Shortages?

It’s easy to blame global supply chains or pandemics, but the real root causes are deeper and more systemic. Over 46% of all drug shortages in 2022 were caused by manufacturing quality failures-things like contamination, equipment breakdowns, or failure to meet FDA standards. These aren’t random accidents. They’re often the result of underinvestment in aging facilities, especially for generic drugs. Most of the affected drugs are generic sterile injectables: things like saline, morphine, vancomycin, and chemotherapy agents. These are cheap to make, so manufacturers don’t invest much in redundancy. Just three companies control 75% of the U.S. supply for many of these critical injectables. If one plant shuts down for a quality issue, the entire country feels it. Even worse, the economics don’t add up. Medicare Part B pays a fixed price for many generic drugs, and Medicaid’s inflation rebate formula makes it unprofitable for manufacturers to raise prices even when costs go up. So they cut corners-on maintenance, staffing, or quality controls-until something breaks. Meanwhile, 80% of the active ingredients in U.S. drugs come from overseas, mostly China and India. A single factory shutdown overseas can ripple through the entire U.S. supply chain.Who Gets Hit the Hardest?

It’s not just hospitals. Rural clinics, safety-net hospitals, and outpatient cancer centers are hit hardest. A 2023 study from the American College of Physicians found that 78% of safety-net hospitals had to delay or cancel procedures because drugs weren’t available. Patients in low-income areas are more likely to get substituted with unfamiliar drugs, increasing the risk of errors. Nurses and pharmacists are on the front lines. A 2022 survey by ASHP showed 92% of hospital pharmacists reported increased workload during shortages. Many worked over 12 extra hours a week just to track down alternatives, adjust dosing, and communicate with doctors. Nurses reported average patient wait times for critical meds jumped by 22 minutes. That’s not just a delay-it’s a risk to survival for someone in septic shock or having a heart attack. And it’s not just about availability. When you switch from morphine to hydromorphone because the first is gone, you’re dealing with a drug that’s five times more potent. One wrong dose, and you’re looking at respiratory arrest. Reddit threads from pharmacists in 2023 documented a 15% spike in medication errors during these transitions.What Hospitals Are Doing Right

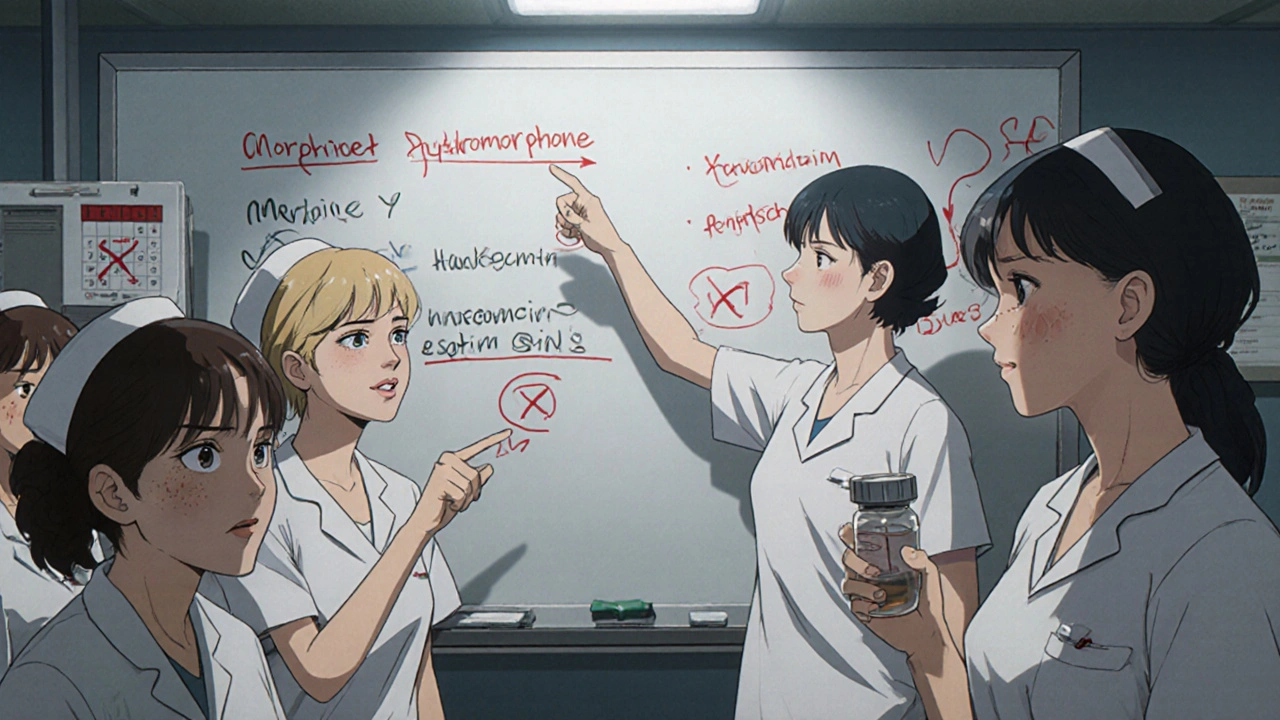

Some hospitals are fighting back-with structure, not luck. The key is having a shortage management team that meets weekly, not just when things fall apart. This team should include pharmacy, nursing, finance, IT, and risk management. No one person should be left to scramble alone. They’re also building buffers. ASHP recommends keeping 14 to 30 days’ supply of critical drugs on hand. But only 35% of hospitals can afford that. Safety-net hospitals average just 8 to 12 days. Still, even a few extra days can mean the difference between switching drugs and keeping patients stable. One hospital in Minnesota started tracking every shortage in a digital log: when it was detected, what alternatives were considered, who was notified, and whether any errors occurred. Within a year, they cut medication errors during shortages by 40%. Simple tracking made them proactive. Training matters too. Hospitals that run quarterly simulation drills-where teams practice switching from one drug to another under pressure-see 33% fewer errors when real shortages hit. These aren’t theoretical exercises. They’re role-playing real scenarios: “Your IV morphine just arrived but it’s 30% less than ordered. What do you do?”

What You Can Do Right Now

You don’t need a hospital-wide committee to start protecting your patients. Here’s what you can do today:- Know your top 10 at-risk drugs. Check the FDA’s Drug Shortage Database daily. It’s free and updated in real time. Focus on sterile injectables-these are the most fragile.

- Build a local alternative list. For each critical drug, identify one or two clinically appropriate substitutes. Don’t wait until the last minute. Talk to your pharmacy team now. Document dosing conversions. Print it out. Post it in the med room.

- Track your own inventory. Don’t wait for the vendor to call. Check your stock twice a week. If you’re down to a week’s supply, flag it. Don’t assume someone else is handling it.

- Communicate early. If a drug is running low, tell the team. Don’t wait for the pharmacy to send an email. Say it at huddle. Write it on the whiteboard. Silence kills.

- Document everything. If you had to use a substitute, note it in the chart. If a patient had a reaction, log it. That data helps your hospital push for better solutions later.

Why the System Is Failing-and What’s Changing

The U.S. system relies on voluntary reporting from manufacturers. Only 65% of them report shortages on time, according to ASHP. That’s like asking firefighters to call in when they see smoke. It’s not enough. The FDA is working on new rules. Their draft guidance, expected to finalize in 2024, will require manufacturers to report potential shortages at least six months in advance. That could cut detection delays by 25%. But enforcement is still weak. Some states are stepping in. California passed a law requiring hospitals to report shortages to the state health department. Others are exploring state-level stockpiles. Germany keeps national reserves of critical drugs-and cut shortage impacts by over half during the pandemic. The U.S. has no such system beyond the Strategic National Stockpile, which only covers bioterrorism and disasters, not routine drug failures. The real fix? Money. The American College of Physicians wants Medicare to reward manufacturers who maintain reliable production. Right now, the system punishes quality. If a company invests in better equipment and avoids shutdowns, they don’t get paid more. They get paid the same as the one who cut corners. That needs to change.

What to Do When You’re Out of Options

Sometimes, no alternative is perfect. You’re out of vancomycin. You’ve used all your alternatives. What then? First, don’t guess. Call your pharmacy. Ask: “Is there a therapeutic equivalent? What’s the dosing conversion? What are the risks?” Second, talk to the patient. Explain: “We’re out of your usual medication. We’re switching to this one. Here’s why it’s safe, and what to watch for.” Third, escalate. If you’re in a clinic and can’t get the drug, contact your regional health network. Ask if another facility has extra stock. Many hospitals will share with nearby ones during shortages. And never, ever skip documentation. Even if you’re improvising, write it down. It protects the patient. It protects you. And it builds the case for systemic change.The Bottom Line

Medication shortages aren’t going away. They’re getting worse. By 2030, experts predict a 10% annual increase in shortages, especially for cancer, anesthesia, and ICU drugs. But you’re not powerless. The tools to manage them exist. They’re not fancy. They’re simple: awareness, preparation, communication, and documentation. You can’t control the supply chain. But you can control how your team responds. Start today. Know your drugs. Know your alternatives. Talk to your team. Document everything. That’s how you protect your patients-not just when the drugs arrive, but when they don’t.What are the most common drugs in shortage right now?

As of late 2024, the most frequently shorted drugs are generic sterile injectables: morphine, vancomycin, norepinephrine, propofol, and IV saline. Cancer drugs like doxorubicin and cisplatin also face frequent shortages. These are all critical for emergency care, surgery, and chemotherapy. Check the FDA’s Drug Shortage Database daily for real-time updates.

Can I legally substitute one drug for another during a shortage?

Yes, if the substitute is therapeutically equivalent and approved by your institution’s pharmacy and therapeutics committee. For example, hydromorphone can replace morphine, but dosing must be adjusted (1 mg hydromorphone ≈ 5 mg morphine). Always follow your hospital’s protocol and document the substitution clearly in the medical record. Never substitute without confirming safety and dosing with a pharmacist.

How do I know if a drug shortage is coming before it happens?

Monitor the FDA’s Drug Shortage Database daily. Also, watch for supply chain red flags: if your vendor starts shipping partial orders, delays deliveries, or says “limited availability,” that’s an early warning. Some hospitals use automated alerts from pharmacy software that syncs with FDA data. Proactive teams check inventory weekly and flag anything below two weeks’ supply.

Why are generic drugs more likely to be in shortage than brand-name ones?

Generic drugs have thin profit margins. Manufacturers compete on price, not quality or reliability. Many use older facilities with outdated equipment. If a plant fails an FDA inspection, there’s often no backup supplier because no one else is making it. Brand-name drugs have higher prices and often multiple manufacturers, so they’re less vulnerable.

Is it safe to use a drug from a different manufacturer during a shortage?

Yes, if the drug is bioequivalent and approved by the FDA. All generic drugs must meet the same standards as brand-name versions. However, inactive ingredients (like preservatives or solvents) can vary, which may affect stability or compatibility. Always verify with your pharmacist. For IV drugs, check for particulate matter or discoloration before use. Never assume all generics are identical-small differences matter in critical care.

Rebecca Parkos

November 2, 2025 AT 14:25Let me tell you something-this isn’t just about drugs. It’s about greed. Hospitals are getting screwed because Big Pharma and the FDA are in bed together. I’ve seen nurses cry because they had to give a dying patient a cheaper, weaker version of morphine. And the company that makes it? They shut down their plant because profits were down. No one gets fired. No one goes to jail. Just more patients suffering. This is systemic murder dressed up as policy.

Bradley Mulliner

November 4, 2025 AT 08:23It’s not a shortage-it’s a failure of leadership. Anyone who thinks this is just about manufacturing is delusional. The real issue? Nurses and pharmacists aren’t trained to manage alternatives properly. You don’t just swap morphine for hydromorphone and call it a day. You need protocols. You need competency assessments. You need accountability. And no one wants to admit they’re unprepared. That’s why people die.

Rahul hossain

November 4, 2025 AT 16:06As someone from India, I see this daily. The same factories that produce our generics are the ones failing inspections in the U.S. Why? Because the price is so low, even a 5% profit margin is considered generous. The FDA demands perfection-but pays pennies. It’s like asking a street vendor to serve Michelin-star food with a $1 budget. The system is designed to fail. No one wants to pay for quality. So quality dies.

Reginald Maarten

November 4, 2025 AT 20:27Actually, the data is misleading. The FDA reports 20% shortage rates, but that includes minor, transient disruptions. The real crisis is concentrated in 5–7 drugs-morphine, vancomycin, norepinephrine, propofol, saline, doxorubicin, and cisplatin. Everything else is noise. Also, ‘10-month average’ is skewed by outliers. The median is 3.2 months. And yes, some shortages are caused by manufacturing failures-but 40% of those are due to human error during reconstitution, not plant defects. Stop blaming corporations. Start blaming incompetent staff who don’t follow SOPs.

Jonathan Debo

November 5, 2025 AT 14:23Let’s be precise: the issue isn’t ‘medication shortages’-it’s ‘therapeutic supply chain fragmentation due to regulatory arbitrage and cost-driven production decentralization.’ The FDA’s voluntary reporting framework is archaic. Manufacturers are not incentivized to report in advance because there are no penalties for late disclosure-and no rewards for proactive resilience. Furthermore, the Medicare Part B reimbursement model is fundamentally misaligned with production economics. Until we implement risk-adjusted pricing for generic injectables-tied to reliability metrics-this will persist. Also, ‘check your inventory twice a week’? That’s not a solution. That’s a Band-Aid on a hemorrhage.

Robin Annison

November 7, 2025 AT 00:13I’ve been a pharmacist for 22 years. I’ve seen this cycle repeat since the 90s. It’s heartbreaking. But here’s what I’ve learned: we’re not powerless. We just keep thinking in terms of systems, when we need to think in terms of people. The nurse who writes down every substitution? She’s not just documenting-she’s bearing witness. The pharmacist who calls three hospitals to find a vial? That’s solidarity. We don’t need new laws. We need to stop treating each other like cogs. When you talk to your team-really talk-you find solutions no playbook can predict. It’s not about fixing the supply chain. It’s about rebuilding trust.

George Clark-Roden

November 8, 2025 AT 13:18Every time I read this, I cry. Not because I’m weak-because I’ve held a mother’s hand while she waited 47 minutes for norepinephrine because the IV bag was ‘out of stock.’ Her son was 8. He had sepsis. He didn’t die. But he almost did. And it wasn’t because of bad medicine. It was because the system forgot that people matter more than profit margins. I work in a rural ER. We keep a shoebox with handwritten dosing charts taped to the wall. We don’t have a digital log. We don’t have a committee. We have each other. And sometimes-that’s enough. But it shouldn’t have to be.

Nishigandha Kanurkar

November 10, 2025 AT 04:35China is poisoning our medicine. It’s not a shortage-it’s a bio-warfare attack. They control 80% of the ingredients. They shut down plants on purpose to force us to pay more. The FDA? They’re in on it. They inspect factories with a flashlight and a smile. Why? Because the CEO of Pfizer donates to their PAC. They’re letting us die so they can sell us expensive brand-name drugs. You think this is about money? No. It’s about control. Wake up.

Lori Johnson

November 11, 2025 AT 13:18Okay but-can we talk about how nurses are being treated? Like, I get that the system is broken, but the people on the ground are being asked to do impossible things without support. I’m not saying blame the nurses-but they’re the ones getting yelled at when a patient has a reaction to a substitute. No one asks if they had training. No one asks if they had time. No one asks if they were given the right tools. They’re just told to ‘figure it out.’ That’s not leadership. That’s cruelty disguised as efficiency.

Tatiana Mathis

November 12, 2025 AT 20:14I’ve spent the last six months working with a safety-net hospital in Alabama, and I can tell you this: the most effective intervention wasn’t a new protocol or a new database-it was a weekly huddle where the nurse, pharmacist, and charge doctor sat down and just talked. No slides. No PowerPoint. Just: ‘What’s broken? What scared you this week? What did you wish you’d known?’ That’s it. And within three months, near-misses dropped by 60%. People don’t need more rules. They need to feel seen. When you create space for vulnerability, solutions emerge. It’s not rocket science-it’s human connection.

Michelle Lyons

November 13, 2025 AT 02:05They’re hiding the real reason. The government is deliberately allowing shortages to push people toward private insurance and telehealth. You think they want you to have cheap morphine? No. They want you to pay $500 for an app that ‘recommends’ a substitute. Then they sell your data to pharma. This is all part of the Great Healthcare Consolidation. The shortages? Just the first step. Next, they’ll ration insulin. Then dialysis. Watch the news. They’re already testing it in Puerto Rico.

Cornelle Camberos

November 13, 2025 AT 03:24It is imperative to recognize that the current paradigm of pharmaceutical supply chain management is fundamentally incompatible with the principles of public health. The absence of mandatory reporting, the lack of federal stockpiling infrastructure, and the absence of financial incentives for manufacturing resilience constitute a catastrophic policy failure. To suggest that individual clinicians can mitigate this crisis through inventory checks is not only naive-it is dangerously irresponsible. The responsibility lies squarely with federal regulatory bodies, which have abdicated their duty to safeguard the population’s health.

joe balak

November 14, 2025 AT 04:55Check the FDA site. Every day. Keep a notebook. Print the list. Put it on the fridge. That’s it. No committees. No apps. No drama. Just know what’s out. And if you’re out? Call the pharmacy. They’ll tell you what to do. Simple.

Iván Maceda

November 15, 2025 AT 07:43🇺🇸 We built the best medical system in the world. Now we’re letting it crumble because we’re too lazy to pay for it. Other countries have national stockpiles. We have TikTok trends. 🤡 Fix the system. Don’t blame the nurses. Don’t blame the pharmacists. Blame the politicians who won’t fund it. And stop outsourcing everything to China. Make the drugs here. Pay the workers. It’s not that hard.

Vrinda Bali

November 17, 2025 AT 00:30The Indian government has long understood that pharmaceutical sovereignty is national security. We export generics to the world, but we never allow our own critical drugs to be in shortage. Why? Because we mandate dual sourcing. We require every manufacturer to maintain backup facilities. We subsidize quality upgrades. We track every batch in real time. The U.S. could do this tomorrow-if it had the will. Instead, it chooses convenience over life. The moral failure is not in the factories. It is in the Congress.